An Intelligent Design Platform for Aeroengine Blades Based on Mesh Automatic Generation Technology.

Computational Fluid Dynamics (CFD) simulation is the main tool for modern aero-engine turbine blade design, and mesh generation is an essential part of CFD simulation. However, using traditional commercial mesh generation software to generate complex turbomachinery structured meshes typically requires a lot of manual operations and can take an engineer several days. In addition, when multidisciplinary optimisation design is carried out on blades, the presence of film cooling holes can lead to a significant rise in the amount of mesh, greatly increasing the calculation time and extending the design cycle.

We therefore aim to build an intelligent design platform for aero-engine blades, called NuFlux, which will integrate our developed algorithms for automatic structured mesh generation of aero-engine blades, enabling automatic mesh generation within minutes.

The platform will also integrate a blade geometry parametric design system, a mesh quality check system and a CFD solver module. The CFD solver module will integrate the multiscale algorithms developed by our team to achieve fine flow field calculation results on coarse meshes. Using this platform, blade designers can complete the whole aero-engine blade design process, accelerate the blade design cycle and achieve rapid blade design optimisation.

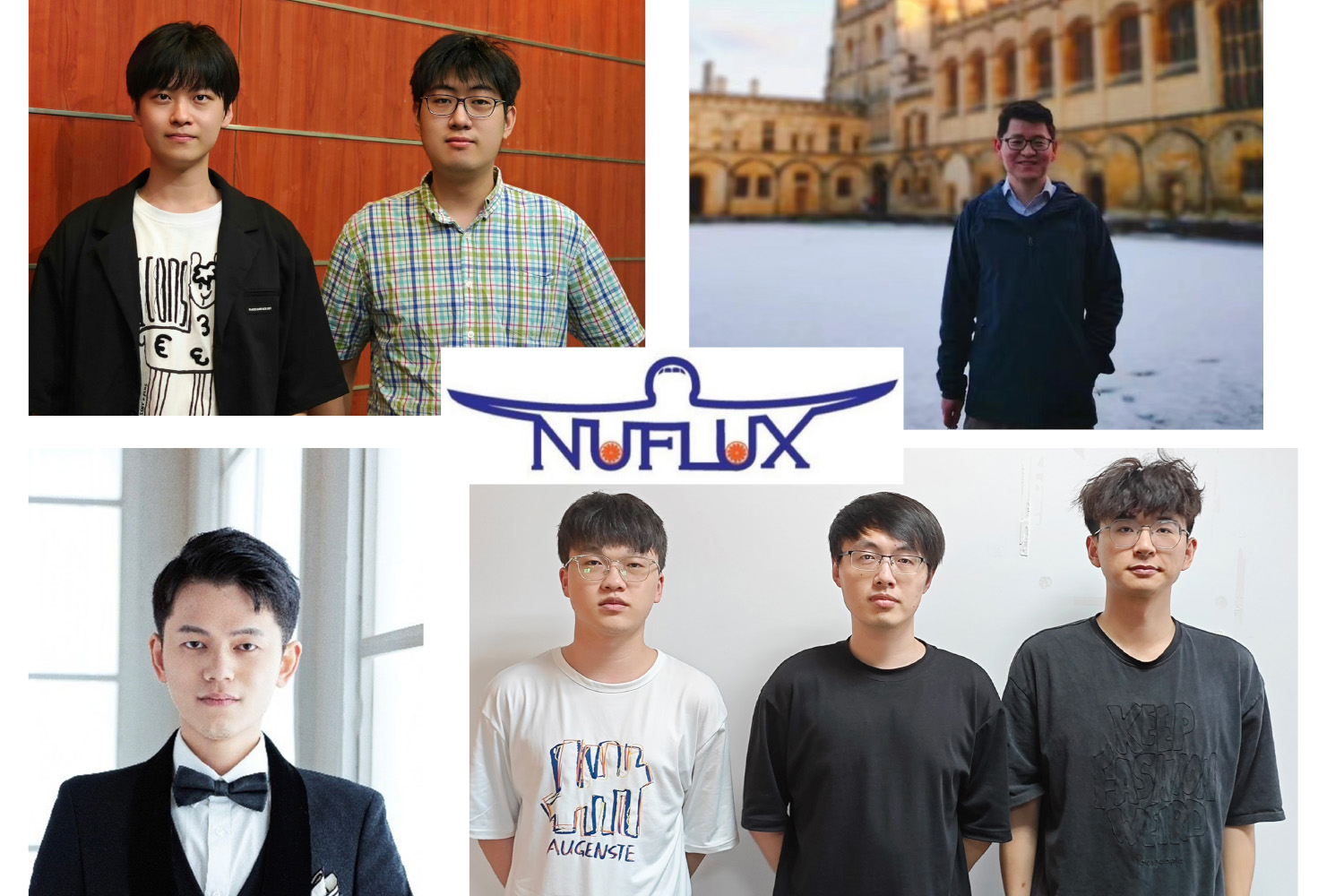

Mr Fan Jiazheng* (Res Asst, Department of Mechanical Engineering, City University of Hong Kong)

Mr Jiang Shan (The Hong Kong University of Science and Technology)

Dr Wang Wei (Northwestern Polytechnical University)

Mr Han Chuang (Zhejiang University)

Mr Shi Xurong (Suzhou Institute of Technology, Jiangsu University of Science and Technology)

Mr Yang Tongzhao (Chongqing Electronic Engineering Vocational College)

* Person-in-charge

(Info based on the team's application form)

- CityU HK Tech 300 Seed Fund (2023)