Graphene face masks that battle bacteria

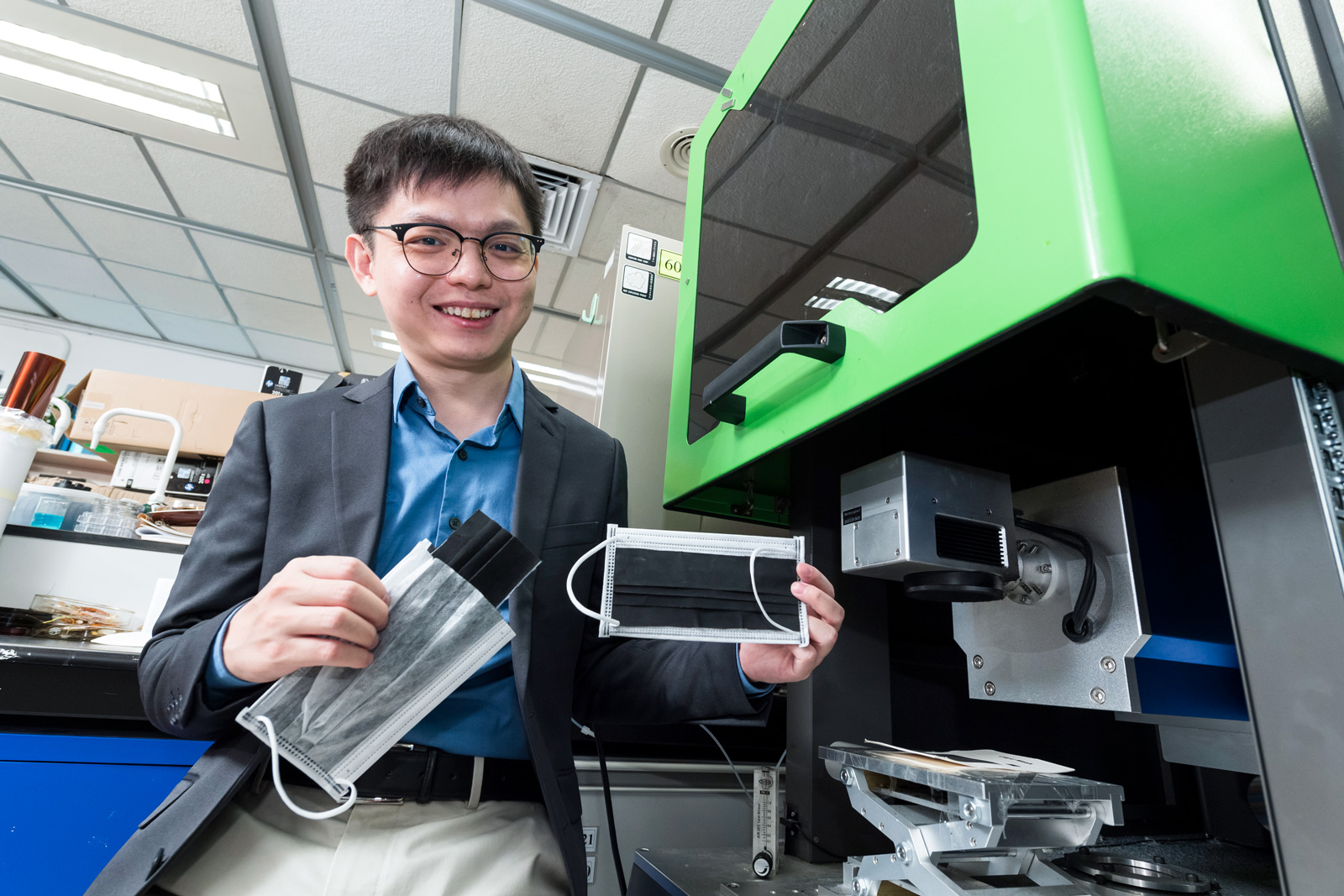

A new method for making anti-bacterial graphene masks quickly and cost effectively has been discovered by Dr Ye Ruquan, Assistant Professor in the Department of Chemistry, and his team at City University of Hong Kong (CityU). The masks have the potential to combat viruses as well.

Commonly used surgical masks are not antibacterial and so harmful elements can remain active for hours, which poses a risk of secondary infection. However, graphene is known for its antibacterial properties, and so scientists have studied the possibility of making graphene masks.

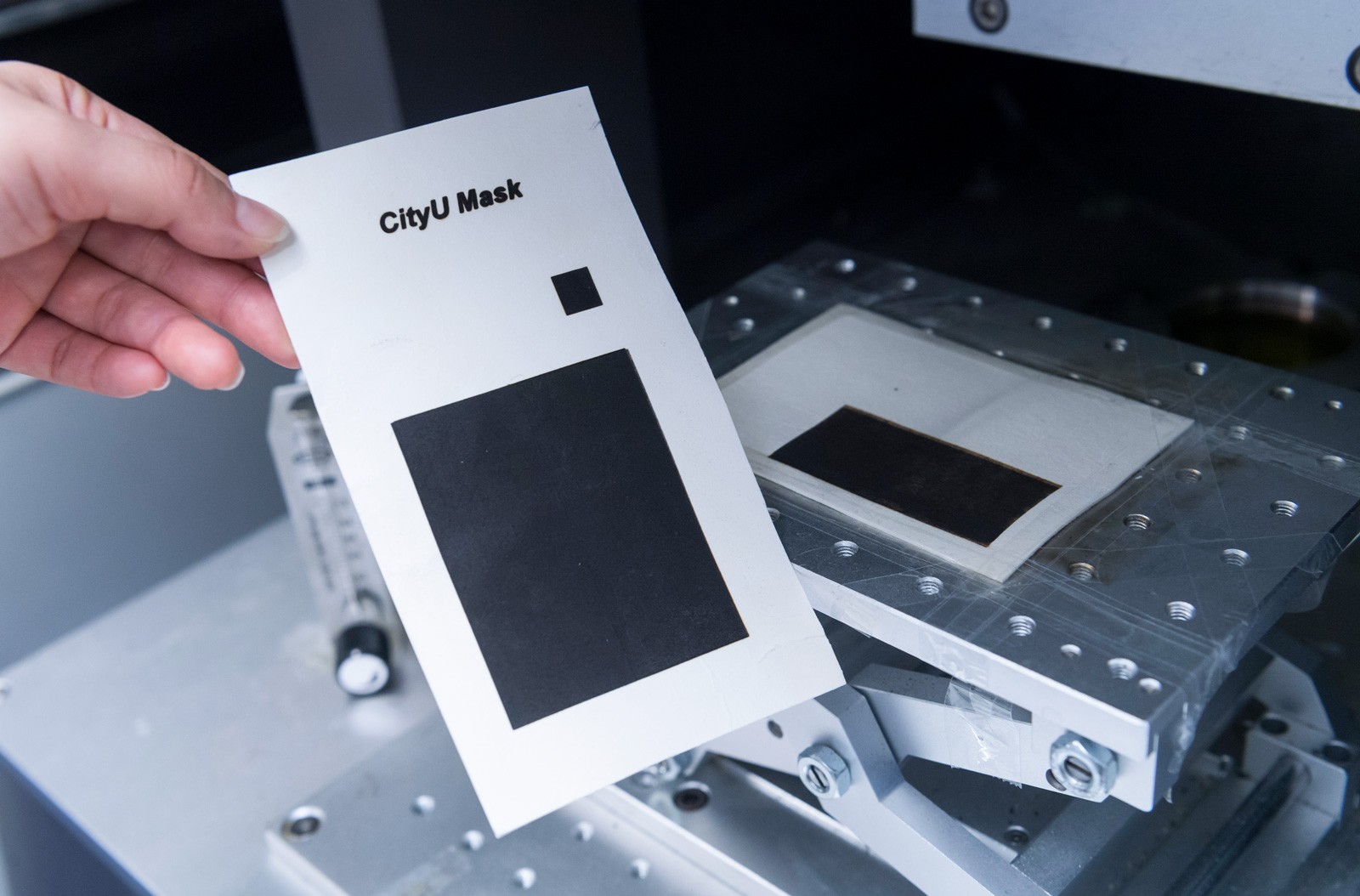

“In previous studies conducted a few years ago, we found that direct writing on commercial polyimide films [a polymeric plastic material] or other biomaterials using a commercial CO2 infrared laser system can generate 3D porous graphene, which makes the fabrication of graphene masks quick and easy,” Dr Ye said.

Preliminary studies on the anti-bacterial graphene masks are already underway. “Our laser-induced graphene [LIG] material can kill almost all the E. coli and aerosolized bacteria. The bacteria-killing activity is induced by the graphene–bacteria interactions,” Dr Ye explained. Under the photothermal effect of the sun, it was possible to kill bacteria with an efficiency of 99.998% within 10 minutes.

In addition, the team has recently begun testing LIG material's ability to combat viruses and has achieved very promising results. Initial tests on two coronaviruses found that the LIG material inactivated over 90% of the virus in five minutes and all of them in 10 minutes.

Conventional methods for producing graphene include chemical vapour deposition in which graphene is first grown on a porous substrate at high temperatures and the substrate is subsequently etched; and the hydrothermal method in which graphene oxide collects together and is simultaneously reduced in hot water.

But these two methods have poor control over the shape of the product and require high-temperature conditions, lengthy synthesis routes, and high costs.

Dr Ye’s breakthrough combines graphene preparation and patterning into a single step. The method is time and cost effective and may help to resolve the problem of sourcing raw materials. Most carbon containing materials, for example cellulose or paper, can be converted into graphene.

“We can also use biomass or biomaterials as well. It is a green technique,” Dr Ye pointed out.

In addition, the conversion can be carried out under ambient conditions with a laser system found in most machine shops. “I think production streamlining should be simple and the price is expected to fall in between that of a surgical mask and a N95 mask,” he said.

Under computer control, the LIG can be patterned into various shapes with a porous structure. The masks are made comfortable for breathing by adjusting the laser power to modify the size of the pores.

“Our next plan is to evaluate the antivirus efficiency and develop a reusable strategy,” Dr Ye said.

The LIG material has a range of other applications such as fabricating antibacterial medical devices.

“We have made a face mask prototype, and with an optimal structure, we envision releasing it to the market shortly after obtaining the certified tests,” Dr Ye added.

The team has also fabricated a hygroelectric generator powered by human breath that can self-report on the condition of a mask. The adhesion of bacteria or atmospheric particles on the LIG changes surface properties and affects moisture-induced potential, which provides information on the condition of a mask. This kind of mask improves the protection effect, which is especially important for frontline workers.

The CityU research team includes Huang Libei, Su Jianjun, Song Yun, PhD students, and Xu Siyu, MSc student, all from the Department of Chemistry. The work is collaborated with the teams from Professor Tang Ben-zhong, the Hong Kong University of Science and Technology; Dr Zhu Chunlei, Nankai University and Dr Chen Sijie, Karolinska Institutet (Hong Kong).