New approach for making high-strength and ductile alloys

A research team led by City University of Hong Kong (CityU) has discovered a new strategy for fabricating multicomponent superlattice alloys with disordered interfacial nanolayers that have both high strength and good ductility at various temperatures.

The findings have been published in the prestigious scientific journal Science under the title “Ultra high-strength and ductile superlattice alloys with nanoscale disordered interfaces”.

Superlattice alloys have an atomically close-packed and ordered structure. The strong chemical binding and low atomic mobility make them very attractive to high-temperature structural applications in a range of engineering fields such as aerospace, automotive, gas turbine engine, and many other industries.

However, the highly ordered crystalline structure makes them brittle.

The research team led by Professor Liu Chain-tsuan, University Distinguished Professor in the College of Engineering, has discovered a new approach to resolving this dilemma.

According to conventional wisdom, adding trace amounts (0.1 to 0.5 atomic percent (at. %)) of boron substantially improves their tensile ductility by increasing grain-boundary cohesion, but when more than 0.5 at. % of boron were added, this traditional approach would not work well. However, the team came up with the idea to add excessive amounts of boron to the multicomponent alloys, and the results were to their surprise.

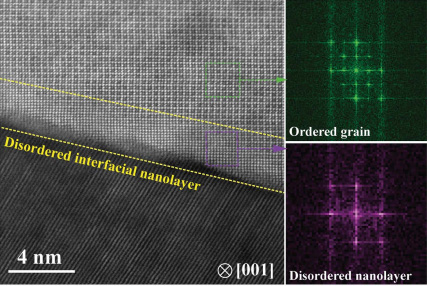

“By increasing the boron concentration to 2.5 at. %, the alloy that we synthesised has an ultra-thin disordered interfacial nanolayer along the grain boundary,” said Professor Liu.

The ultra-thin layer contains multiple principal elements with disordered atomic structures that prevent brittle intergranular fractures.

The general structure of superlattice alloys is made of individual crystalline areas known as “grains”. The brittleness in these alloys is generally ascribed to cracking along their grain boundaries during tensile deformation.

“Our superlattice materials have ultra-high strengths of 1.6 gigapascals (unit of pressure) with tensile ductilities of 25% at room temperatures, which makes them a lot more ductile than expected,” he added.

In addition, the team discovered that the increase in grain size was negligible even after 120 hours of heating at temperatures of 1050°C.

Most traditional structural materials suffer from thermally driven structural instability because of a rapid grain growth at high temperatures. As a result, the strength of these materials decreases quickly, severely limiting their use.

The research team believes that the nanolayer is pivotal in suppressing growth in grain size and maintaining its strength at high temperatures. The thermal stability of the disordered nanolayer will render this type of alloy suitable for high-temperature structural applications.

The discovery of this disordered nanolayer along the grain boundaries in the alloy will positively impact the development of high-strength materials in the future and may open a pathway for further optimisation of alloy properties.

Professor Liu is the corresponding author of the paper. The co-first authors are Dr Yang Tao and Dr Zhao Yilu from the Department of Mechanical Engineering. Other co-authors from CityU include Professor Huang Chih-ching, Chair Professor of Materials Science and Executive Director of Hong Kong Institute for Advanced Study, Professor Kai Jijung, Chair Professor of Nuclear Engineering, Li Wanpeng from the Department of Materials Science and Engineering, and Dr Luan Junhua at the Inter-University 3D APT Unit.