Breakthrough in High-strength but Ductile Ordered Intermetallic Alloys

The strength-ductility trade-off has always been a dilemma in materials science. The higher the strength of a material, the less the ductility and toughness, meaning that strong materials tend to be less deformable or stretchable without fracture. Professor Liu Chain-tsuan, University Distinguished Professor in the College of Engineering and Senior Fellow of the Hong Kong Institute for Advanced Study (HKIAS) at CityU, together with his team member Dr Yang Tao, Assistant Professor in the Department of Materials Science and Engineering, has developed a novel alloy design strategy to overcome this challenge, paving the way for fabricating materials for operating in extreme temperatures and aerospace systems.

“Most conventional alloys comprise one or two major elements, such as nickel and iron,” Professor Liu explained. “However, by adding aluminium and titanium to form massive precipitates in an iron-cobalt-nickel (FeCoNi)-based alloy, we found a significant increase in both strength and ductility.”

In the prestigious scientific journal Science, they reported that their high-entropy alloy had a superior strength of 1.5 gigapascals, which is five times stronger than FeCoNi based-alloys, and had ductility as high as 50% in tension at ambient temperature.

They also found that adding multicomponent intermetallic nanoparticles can greatly enhance plastic deformation stability, avoiding the common problem of early necking fracture.

Professor Liu believed this innovative strategy would allow the development of alloys that can perform well in temperatures ranging from -200°C to 1000°C, thus providing a good base for developing new cryogenic devices, as well as aircraft and high temperature systems, such as aeronautical engineering applications.

In their other research also reported in Science recently, they revealed a new way to resolve the strength-ductility trade-off effectively by forming disordered nanoscale layers at grain boundaries in ordered intermetallic alloys.

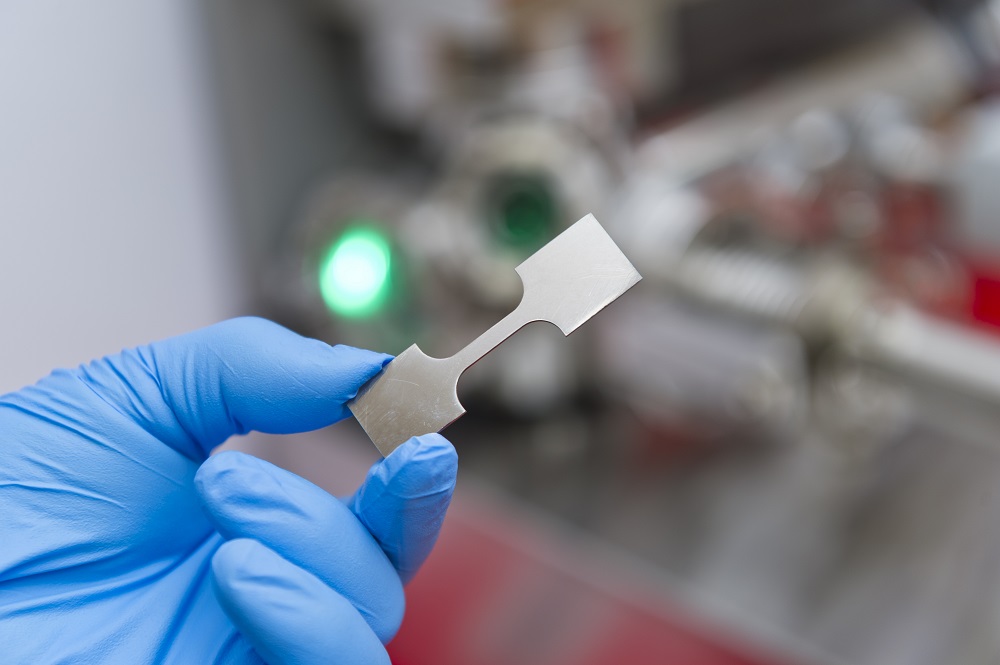

By adding 1.5 to 2.5 atomic percent of boron to an intermetallic alloy, they found that distinctive nanoscale layers were formed between the orderly packed grains in the alloy. “This serves as a buffer zone between adjacent grains, which enables plastic-deformation extensively at the grain boundaries, resulting in the large tensile ductility at an ultra-high yield strength level,” said Dr Yang, who is the first author of the research.

With nanolayers formed at the grain boundaries, the alloy showed an ultra-high yield strength of 1.6 gigapascals, with tensile ductility of 25% at ambient temperature. It also maintained the alloy’s strength with excellent thermal stability at high temperature.

“The discovery of this disordered nanolayer in the alloy will have an impact on the development of high-strength materials in the future, such as structural materials for applications in high-temperature settings, like aerospace, aeronautics, nuclear power and chemical engineering,” said Professor Liu.

Professor Liu, Dr Yang and the team will continue to work on ultra-high strength steels, multicomponent high-entropy alloys, lightweight materials, and nanostructured materials for various applications.

This research article originated from CityU RESEARCH.