One-step solution-coating method to advance perovskite solar cell manufacturing and commercialisation

Perovskite solar cells (PSCs) are considered a promising candidate for next-generation photovoltaic technology with high efficiency and low production cost, potentially revolutionizing the renewable energy industry. However, the existing layer-by-layer manufacturing process presents challenges that have hindered the commercialisation of this technology. Recently, researchers from City University of Hong Kong (CityU) and the National Renewable Energy Laboratory (NREL) in the US jointly developed an innovative one-step solution-coating approach that simplifies the manufacturing process and lowers the commercialisation barriers for PSCs.

“Reducing the number of device-processing steps without sacrificing device efficiency will help reduce the process complexity and manufacturing cost, which will enhance the manufacturability of PSCs,” explained Dr Zhu Zonglong, a co-leader of the research and an assistant professor in the Department of Chemistry at CityU.

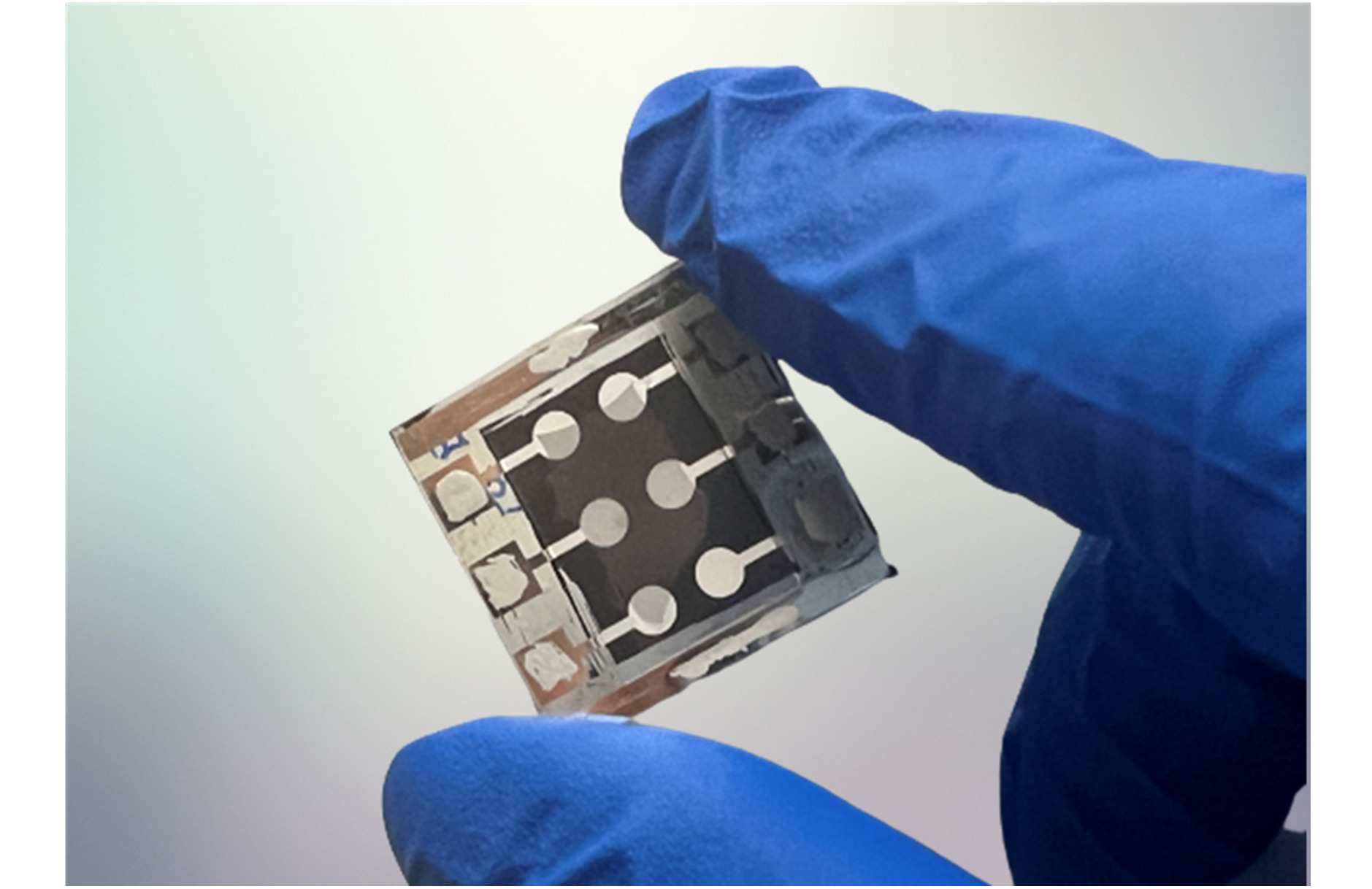

“We addressed the manufacturing issue with a novel approach to co-process the hole-selective contact and perovskite layer in a single step, resulting in state-of-the-art efficiency of 24.5% and exceptional stability for inverted perovskite solar cells. This helps bring the commercialisation of the technology one step closer,” he said.

Typically, PSCs are fabricated using a layer-by-layer process, which involves sequentially depositing different layers of the solar cell on top of each other. While this approach has been successful in producing high-performance perovskite solar cells, it causes issues that may hinder their commercialisation, such as increased fabrication cost, unsatisfactory uniformity and reproducibility.

To improve the manufacturability of PSCs, Dr Zhu collaborated with Dr Joseph M. Luther, from NREL, to jointly invent a new approach for fabricating efficient inverted perovskite solar cells in which the hole-selective contact and perovskite light absorber can spontaneously form in a single solution-coating procedure.

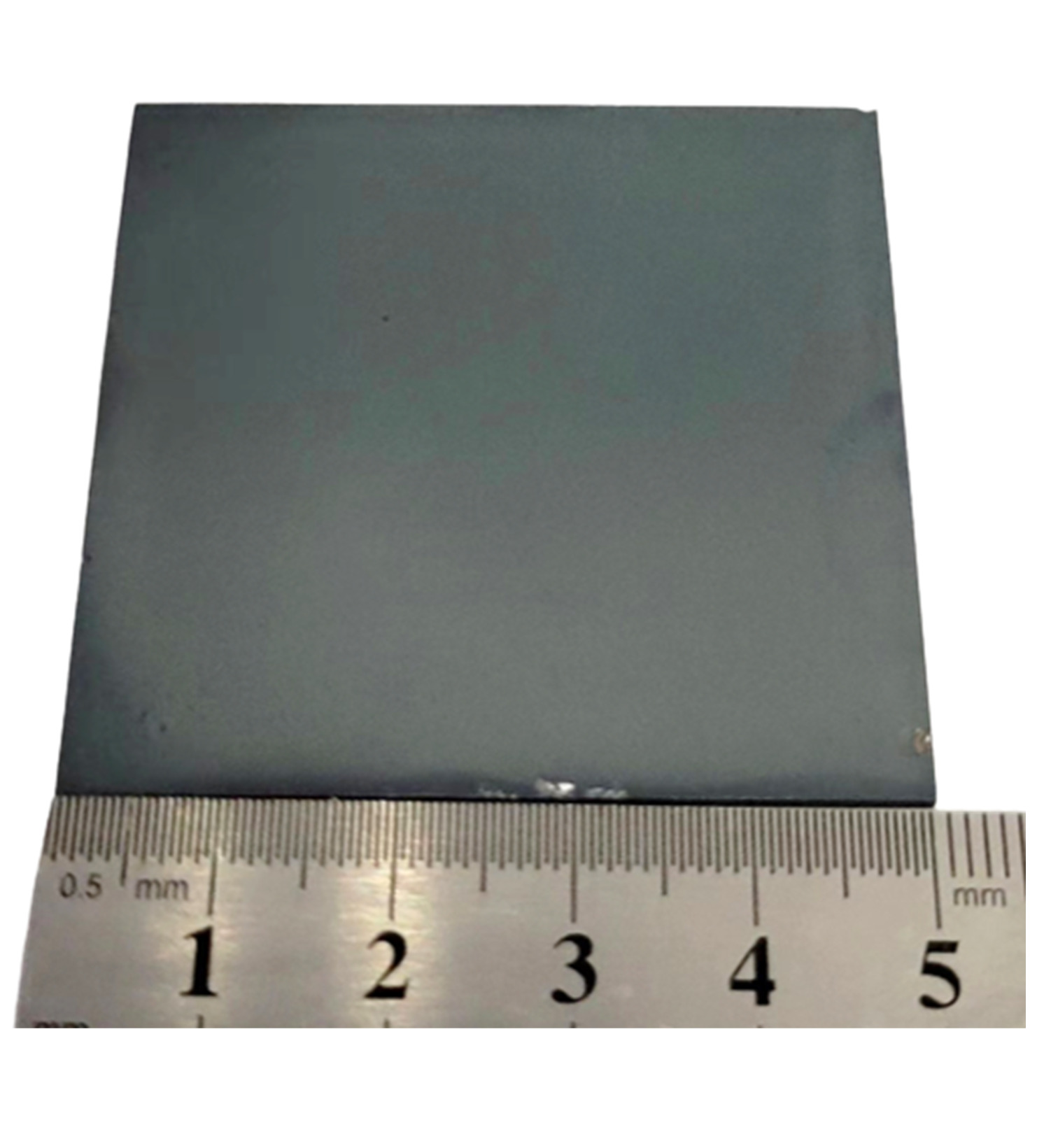

They found that if specific phosphonic or carboxylic acids are added to perovskite precursor solutions, the solution will self-assemble on the indium tin oxide substrate during perovskite film processing. They form a robust self-assembled monolayer as an excellent hole-selective contact while the perovskite crystallizes. This single solution-coating procedure not only solves wettability issues, but also simplifies device fabrication by creating both the hole-selective contact and the perovskite light absorber simultaneously, instead of the traditional layer-by-layer process.

The newly created PSC device has a power conversion efficiency of 24.5% and can retain more than 90% of its initial efficiency even after 1,200 hours of operating at the maximum power point under continuous illumination. Its efficiency is comparable to that of similar PSCs in the market.

The collaborative team also showed that the new approach is compatible with various self-assembled monolayer molecular systems, perovskite compositions, solvents and scalable processing methods, such as spin-coating and blade-coating techniques. And the PSC fabricated with the new approach have comparable performance with those produced from other methods.

“By introducing this innovative approach, we hope to contribute to the perovskite research community by proposing a more straightforward method for manufacturing high-performance perovskite solar cells and potentially accelerating the process of bring them to market,” said Dr Zhu.

The research team plans to further explore the relationship between self-assembled monolayer molecule structures and perovskite precursors to identify an optimal group of self-assembled monolayer molecules for this technique, thereby enhancing the overall performance of the PSCs.

The findings were published in the scientific journal Nature Energy under the title "Co-deposition of hole-selective contact and absorber for improving the processability of perovskite solar cells".

Dr Zhu and Dr Luther are the corresponding authors of the research. The co-first authors are Dr Zheng Xiaopeng and Dr Chen Min from NREL, Mr Li Zhen from CityU, and Dr Zhang Yi from the Institute of Chemical Sciences and Engineering, école Polytechnique Fédérale de Lausanne (EPFL) in Switzerland. The research work conducted at CityU was supported by the Innovation and Technology Fund and the Green Tech Fund in Hong Kong.