New cooling ceramic can enhance energy efficiency for the construction sector and help combat global warming—CityU research

A significant breakthrough in developing a passive radiative cooling (PRC) material has been announced by researchers at City University of Hong Kong (CityU). The findings have just been published in the prestigious scientific journal Science titled “Hierarchically structured passive radiative cooling ceramic with high solar reflectivity.”

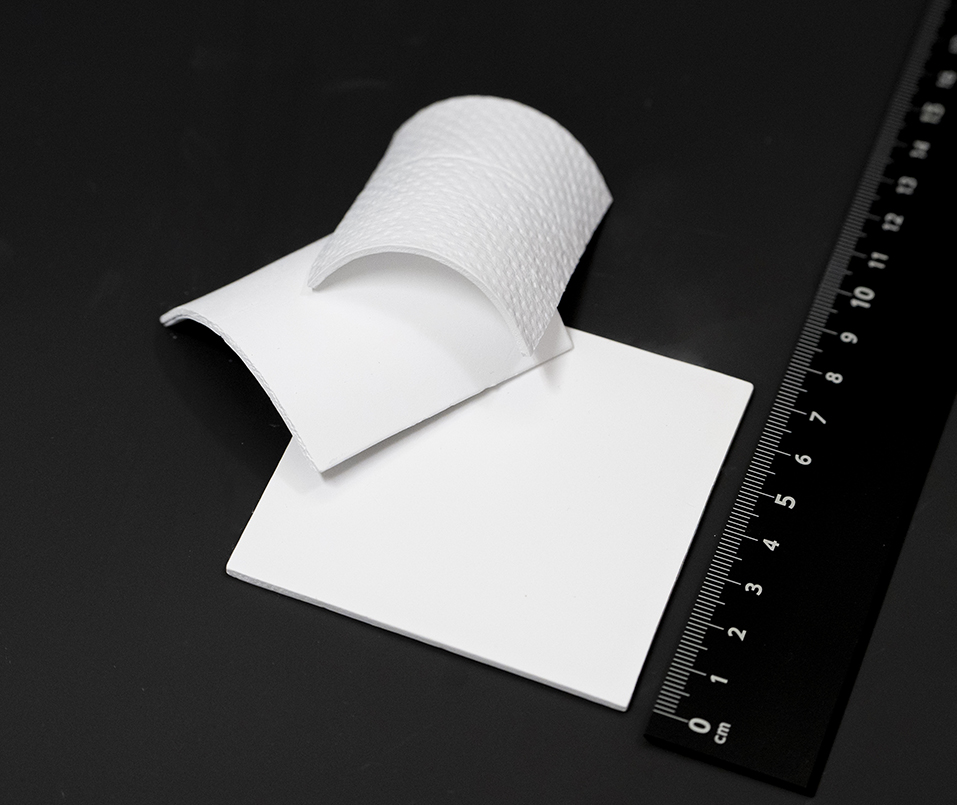

The material, known as cooling ceramic, has achieved high-performance optical properties for energy-free and refrigerant-free cooling generation. Its cost-effectiveness, durability and versatility make it highly suitable for commercialisation in numerous applications, particularly in building construction.

By reducing the thermal load of buildings and providing stable cooling performance, even in diverse weather conditions in all climates, cooling ceramic enhances energy efficiency and can combat global warming.

PRC is considered one of the most promising green cooling technologies for curbing soaring demand for space cooling, reducing environmental pollution, and combating global warming, according to Professor Edwin Tso Chi-yan, Associate Professor in the School of Energy and Environment (SEE) at CityU, one of the corresponding authors of the paper.

However, current PRC using nanophotonic structures are limited by its high cost and poor compatibility with existing end uses, while polymeric photonic alternatives lack weather resistance and effective solar reflection.

Enhanced optical properties and applicability

“But our cooling ceramic achieves advanced optical properties and has robust applicability,” said Professor Tso. “The colour, weather resistance, mechanical robustness and ability to depress the Leidenfrost effect – a phenomenon that prevents heat transfer and makes liquid cooling on the hot surface ineffective – are key features ensuring the durable and versatile nature of the cooling ceramic.”

The cooling ceramic’s extraordinary uniqueness lies in its hierarchically porous structure as a bulk ceramic material, which is easily fabricated using highly accessible inorganic materials such as alumina through a simple two-step process involving phase inversion and sintering. No delicate equipment or costly materials are required, making scalable cooling ceramics manufacturing highly feasible.

Optical properties determine the cooling performance of PRC materials in two wavelength ranges: solar range (0.25-2.5 μm) and mid-infrared range (8-13 μm). Efficient cooling requires high reflectivity in the former range to minimise the solar heat gain and high emissivity in the latter range to maximise the radiative heat dissipation. Owing to the high bandgap of alumina, the cooling ceramic keeps solar absorption to a minimum.

Not only that, by mimicking the bio-whiteness of the Cyphochilus beetle and optimising the porous structure based on Mie scattering, the cooling ceramic efficiently scatters almost all the wavelength of sunlight, resulting in near-ideal solar reflectivity of 99.6% (a recorded high solar reflectivity) and achieves a high mid-infrared thermal emission of 96.5%. These advanced optical properties surpass those of current state-of-the-art materials.

“The cooling ceramic is made of alumina, which provides the desired UV resistance degradation, which is a concern typical of most polymer-based PRC designs. It also exhibits outstanding fire resistance by withstanding temperatures exceeding 1,000 °C, which surpasses the capabilities of most polymer-based or metal-based PRC materials,” said Professor Tso.

Outstanding weather resistance

Beyond its exceptional optical performance, the cooling ceramic exhibits excellent weather resistance, chemical stability and mechanical strength, making it ideal for long-term outdoor applications. At extremely high temperatures, the cooling ceramic exhibits superhydrophilicity, enabling immediate droplet spreading, and facilitating rapid impregnation of the droplets due to its interconnected porous structure. This superhydrophilic characteristic inhibits the Leidenfrost effect that hinders evaporation, commonly found in traditional building envelope materials, and enables efficient evaporative cooling.

The Leidenfrost effect is a phenomenon that occurs when a liquid is brought into contact with a surface significantly hotter than its boiling point. Instead of immediately boiling away, the liquid forms a vapour layer that insulates it from direct contact with the surface. This vapour layer reduces the rate of heat transfer and makes liquid cooling on the hot surface ineffective, causing the liquid to levitate and skid across the surface.

“The beauty of the cooling ceramic is that it fulfils the requirements for both high-performance PRC and applications in real-life settings,” said Professor Tso, adding that the cooling ceramic can be coloured with a dual-layer design, meeting aesthetic requirements as well.

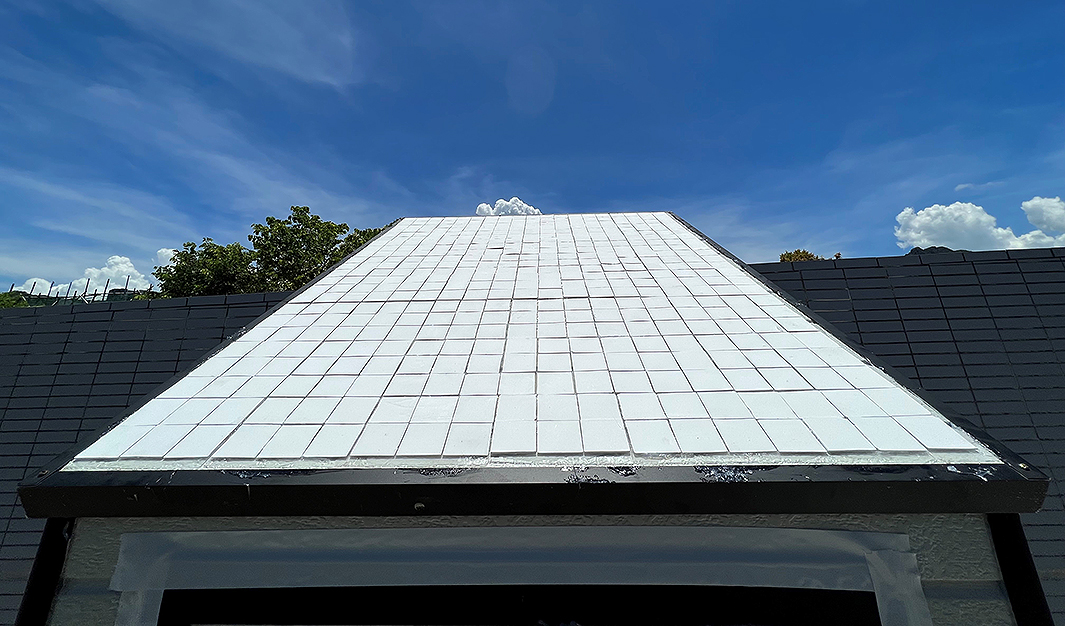

“Our experiment found that applying the cooling ceramic on a house roof can achieve more than 20% electricity for space cooling, which confirms the great potential of cooling ceramic in reducing people’s reliance on traditional active cooling strategies and provides a sustainable solution for avoiding electricity grid overload, greenhouse gas emissions and urban heat islands,” said Professor Tso.

Based on these findings, Professor Tso said the research team intends to advance further passive thermal management strategies. They aim to explore the application of these strategies to enhance energy efficiency, promote sustainability, and increase the accessibility and applicability of PRC technologies in various sectors, including textiles, energy systems, and transportation.

Professor Wang Zuankai, Adjunct Professor in the Department of Mechanical Engineering (MNE) at CityU and Associate Vice-President (Research and Innovation) at the Hong Kong Polytechnic University, is the other corresponding author. The first author, Lin Kaixin, and the second author, Chen Siru, are both PhD students supervised by Professor Tso in CityU's School of Energy and Environment.