CityUHK creates novel metallic glass with dual-high strength and ductility

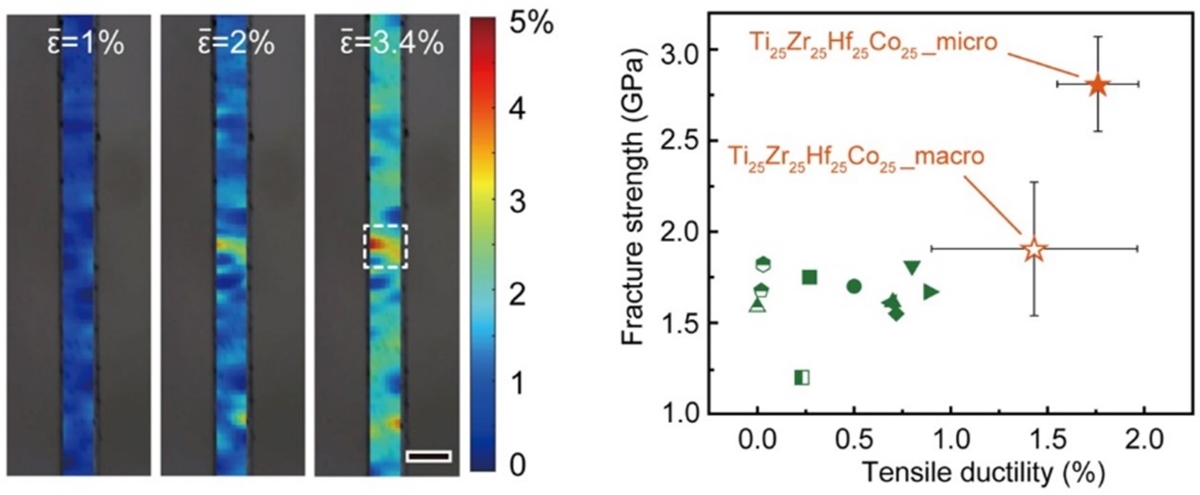

City University of Hong Kong (CityUHK) has recently developed a new multi-principal element metallic glass that shatters previous limitations of tensile ductility. This novel glass is twice as ductile as traditional metallic glasses, and its strength nearly doubles when stretched. The key to this extraordinary property lies in the unique structural evolution of the glass during deformation, which causes it to harden rather than soften, making it significantly more resistant to sudden breakage under tension. The findings surpass limitations of tensile ductility in metallic glasses and provide a promising pathway to create strong and ductile glasses.

“Over the past century, metallic glasses have been widely applied in almost all industrial fields, from commercial products to advanced manufacturing, thanks to their unique combination of properties, such as high elastic limit and superb strength," said Professor Yang Yong, Professor in the Department of Mechanical Engineering at CityUHK, who led the study. “However, traditional metallic glasses have got a bit of a reputation for being brittle due to softening during deformation, especially under tension, which greatly impedes many engineering applications."

He added that the research team successfully achieved strain hardening via fast diffusion of atoms after softening. This unique method allows them to surpass the limitations of tensile ductility encountered in previous methods. By overcoming room-temperature tensile brittleness, our strain-hardening metallic glass has the potential to revolutionize various technological fields.

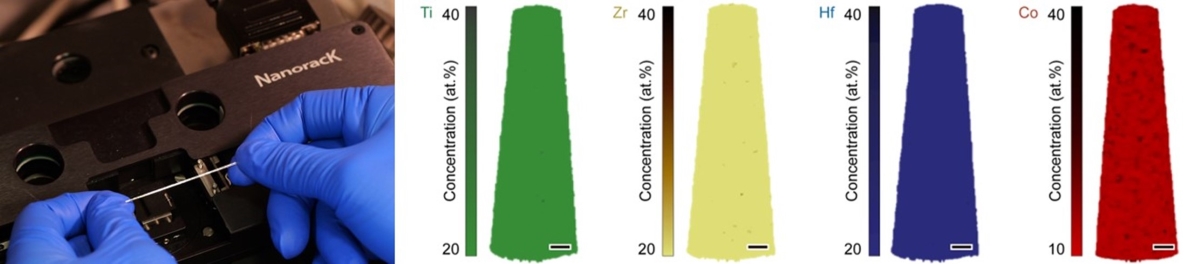

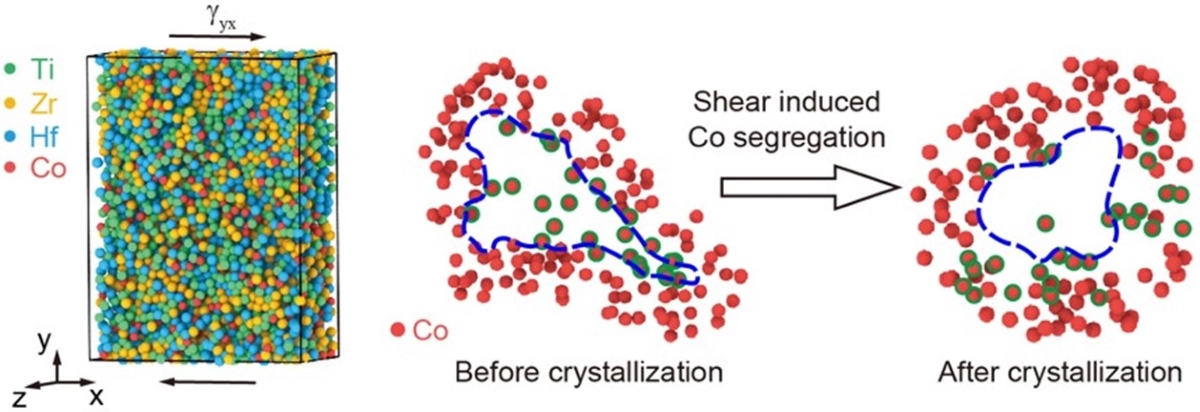

The uniqueness of this research lies in the behavior of the metallic glass during deformation. The fast diffusion and heterogeneous distribution of cobalt (Co) facilitate atomic rearrangement, which interrupts the usual softening process and prompts hardening instead. In contrast, traditional metallic glasses often face a conflict between volume shrinkage from atomic rearrangement and dilation from deformation, leading to cracks and fractures. However, the new multi-principal metallic glass developed by the research team achieves deformation-induced dilation through rearrangement, avoiding the formation of cracks.

The most challenging aspect of the research was overcoming the disordered structure of metallic glass, which lacks the defects that crystals use to achieve hardening during deformation. The team tackled this by promoting atomic rearrangement to counteract softening. However, an accompanying problem is the conflict between dilation induced by tension and shrinkage induced by rearrangement, which results in cracks.

By overcoming the long-standing issue of room-temperature tensile brittleness, metallic glasses are poised to replace traditional alloys in numerous applications, including architectural skeletons and heavy machinery. Additionally, these findings offer a promising direction for alleviating brittleness in other types of glass, such as oxide glasses.

Looking ahead, the research team aims to develop a series of stronger and more ductile metallic glasses based on these findings. They also plan to combine these findings with post-processing techniques to further enhance the ductility of metallic glasses.

The study, titled “Intrinsic tensile ductility in strain hardening multiprincipal element metallic glass” was published in Proceedings of the National Academy of Sciences (PNAS).

The first authors are Mr Zhang Zhibo and Dr Zhang Shan, a PhD student and postdoctoral researcher, respectively, under the supervision of Professor Yang. The corresponding authors are Professor Yang and Professor Guan Pengfei from the Beijing Computational Science Research Center (CSRC). The study was supported by the General Research Fund of the Research Grants Council of Hong Kong and the National Natural Science Foundation of China.

For further inquiries, please contact Professor Yong Yang from the Department of Mechanical Engineering at CityUHK, by email at yongyang@cityu.edu.hk.